I. Análisis de la tecnología de preparación de electrodos secos

1. Introducción a los procesos secos y húmedos y comparación de materiales

El proceso húmedo tradicional implica mezclar material activo, agente conductor y aglutinante en un solvente en proporciones específicas, para luego recubrir la mezcla sobre la superficie del colector de corriente mediante una recubridora de ranura y luego calandrado.

El proceso seco implica mezclar en seco partículas activas y agentes conductores de manera uniforme, agregar un aglutinante, formar una película autoportante a través de la fibrilación del aglutinante y, finalmente, calandrarla sobre la superficie del colector de corriente.

2. Proceso de fabricación de película seca

2.1 Proceso de preparación en seco de película autoportante

Los métodos de película seca incluyen la fibrilación de aglutinante y la pulverización electrostática, siendo la fibrilación de aglutinante la técnica principal. La pulverización electrostática ofrece un rendimiento inferior a la fibrilación de aglutinante en cuanto a procesabilidad, estabilidad de adhesión, flexibilidad del electrodo y durabilidad.

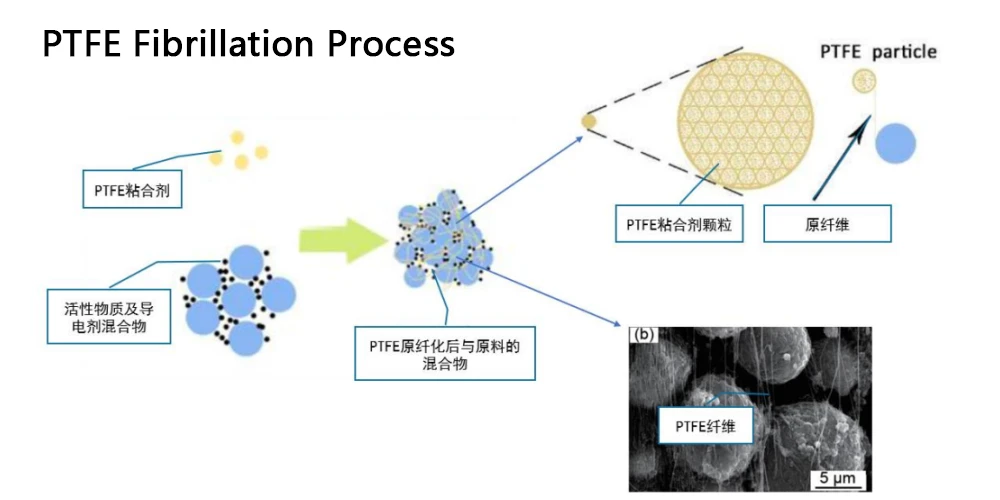

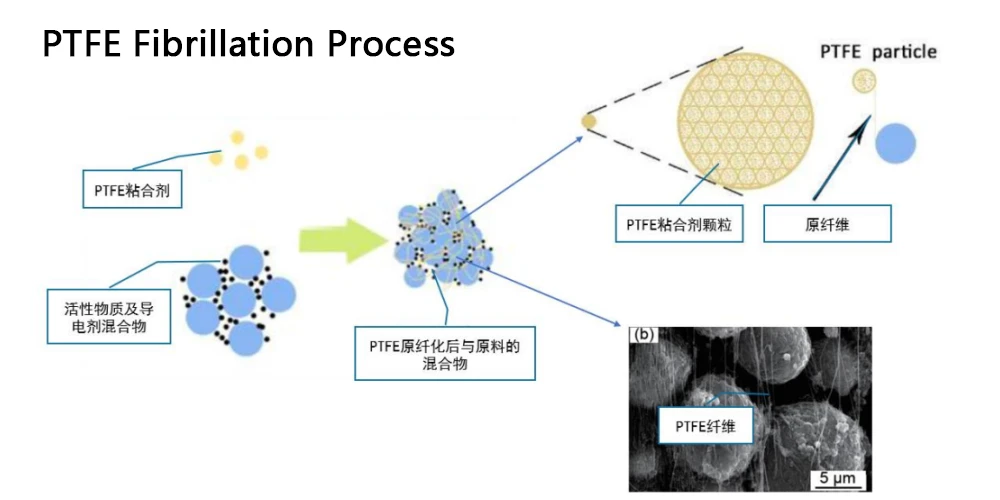

Fibrilación del aglutinante: Se mezcla el polvo de material activo y el agente conductor, se añade el aglutinante de PTFE y se aplica una fuerza de cizallamiento externa para fibrilar el PTFE, uniendo así el polvo de la película del electrodo. La mezcla se extruye para formar una película autoportante.

Pulverización electrostática: El material activo, el agente conductor y las partículas aglutinantes se premezclan con gas a alta presión. El polvo se carga negativamente mediante una pistola de pulverización electrostática y se deposita sobre un colector de corriente de lámina metálica con carga positiva. A continuación, el colector recubierto de aglutinante se prensa en caliente; el aglutinante fundido se adhiere a otros polvos y se comprime formando una película autoportante.

2.2 Principio de la tecnología del proceso seco de fibrilación

La fibrilación transforma el PTFE en fibrillas bajo una fuerza de cizallamiento externa. Debido a las bajas fuerzas de van der Waals del PTFE y a su apilamiento flexible, las fuerzas de cizallamiento convierten los aglomerados en fibrillas que forman un polvo de electrodo que une la red.

La temperatura y el cizallamiento son factores críticos que afectan la fibrilación del PTFE. Por encima de 19 °C, el PTFE pasa de un sistema cristalino triclínico a uno hexagonal, lo que ablanda las cadenas moleculares y facilita la fibrilación.

La producción de películas de fibrilación precede al calandrado de electrodos. Los equipos de fibrilación convencionales incluyen molinos de chorro, extrusoras de tornillo y molinos abiertos.

Tras mezclar bien el PTFE y el material activo, la mezcla se introduce en una máquina de fibrilación. Bajo la presión de un rodillo, forma una película autoportante. Los datos experimentales muestran que una menor velocidad de alimentación aumenta la impedancia de la película del electrodo, mientras que una mayor fuerza de calandrado la reduce.

II. Electrodo seco vs. electrodo húmedo: ventajas y desventajas

1. Menor costo: Reducción del 18% en los costos de fabricación

El proceso seco tiene menos pasos. La producción en masa reduce los costos de fabricación de celdas en un 18 % (0,056 RMB/Wh). En el proceso húmedo, el recubrimiento/secado y la recuperación de solventes representan el 22,76 % y el 53,99 % de los costos de equipo, mano de obra, instalaciones y energía, respectivamente. El proceso seco reemplaza el recubrimiento en suspensión con la formación de una película autoportante, eliminando el solvente NMP, el secado de electrodos y la recuperación de solventes, lo que reduce significativamente los costos.

II. Electrodo seco vs. electrodo húmedo: ventajas y desventajas

1. Menor costo: Reducción del 18% en los costos de fabricación

El proceso seco tiene menos pasos. La producción en masa reduce los costos de fabricación de celdas en un 18 % (0,056 RMB/Wh). En el proceso húmedo, el recubrimiento/secado y la recuperación de solventes representan el 22,76 % y el 53,99 % de los costos de equipo, mano de obra, instalaciones y energía, respectivamente. El proceso seco reemplaza el recubrimiento en suspensión con la formación de una película autoportante, eliminando el solvente NMP, el secado de electrodos y la recuperación de solventes, lo que reduce significativamente los costos.

El proceso seco es más ecológico y escalable. El NMP (N-metilpirrolidona), tóxico, requiere un reciclaje de alto consumo energético en los procesos húmedos. El procesamiento seco sin disolventes simplifica los flujos de trabajo, reduce el espacio ocupado por los equipos y permite la producción de electrodos a gran escala.

2.

Mayor densidad de material activo: aumento del 20 % en la densidad energética

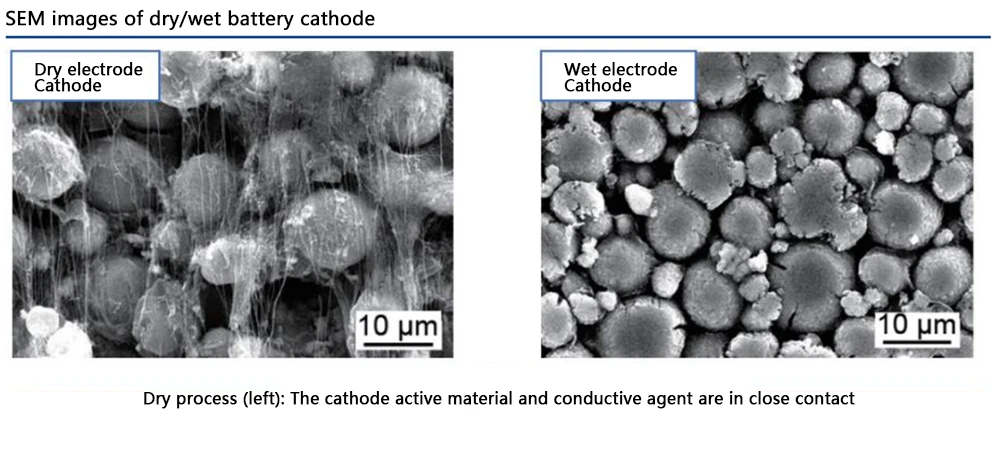

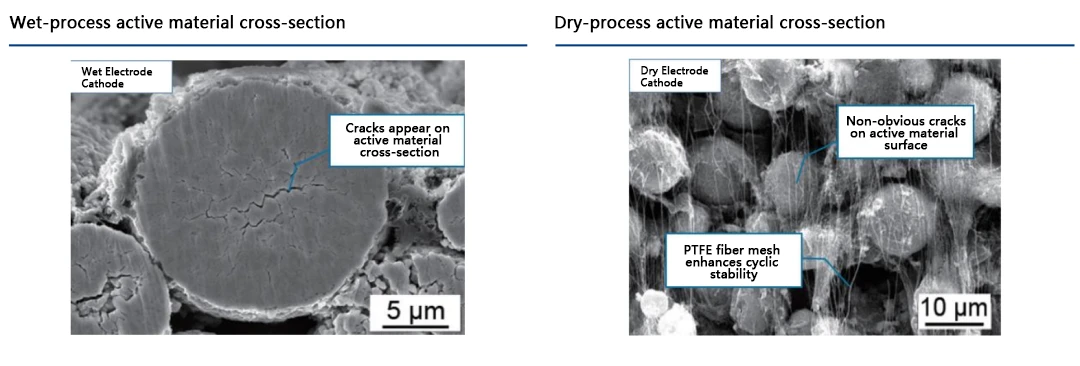

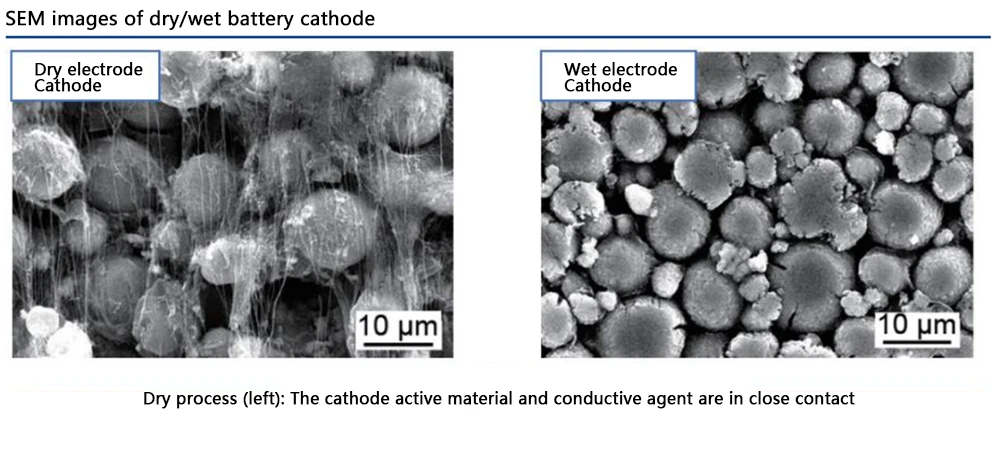

La fibrilación de PTFE permite una morfología más uniforme de los electrodos secos en comparación con los húmedos. La evaporación del disolvente en el procesamiento húmedo crea espacios vacíos entre el material activo y los agentes conductores, lo que reduce la densidad de compactación. Sin secado, los electrodos secos eliminan los espacios vacíos, asegurando un contacto más estrecho entre las partículas.

Los electrodos secos logran una mayor densidad de compactación con menos grietas/microporos:

-

LFP: 2,30 g/cm³ → 3,05 g/cm³ (+32,61%)

-

NMC: 3,34 g/cm³ → 3,62 g/cm³ (+8,38%)

-

Ánodo de grafito: 1,63 g/cm³ → 1,81 g/cm³ (+11,04%)

Un mayor contenido de material activo por volumen permite una mayor densidad energética.

Las baterías secas alcanzan una densidad energética un 20 % mayor en condiciones idénticas. Los datos de Maxwell muestran que los electrodos secos superan los 300 Wh/kg, con un potencial de hasta 500 Wh/kg.

Los electrodos secos admiten límites de espesor mayores (30 µm–5 mm frente a los 160 µm de los húmedos), lo que mejora la capacidad de área y la compatibilidad con diversos materiales activos.

3. Rendimiento eléctrico superior

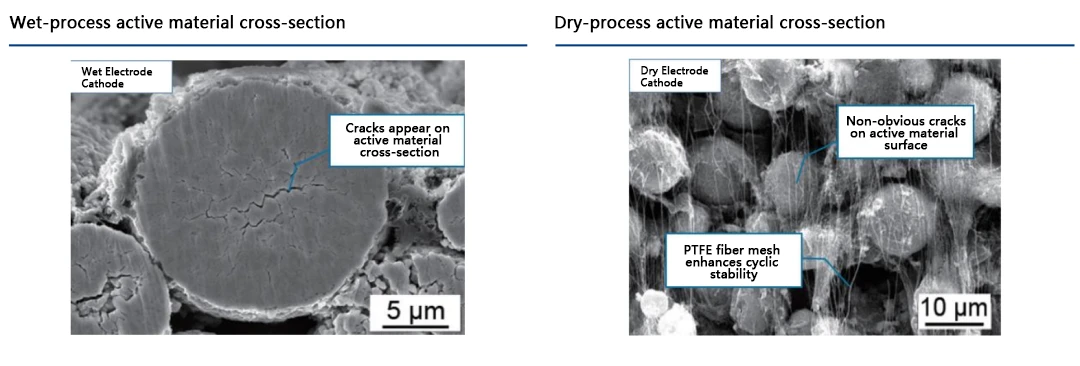

Las pruebas de laboratorio confirman que las baterías de proceso seco destacan por su ciclo de vida, durabilidad e impedancia. La red de fibrillas mejora la estabilidad del material y el rendimiento eléctrico.

En el procesamiento húmedo, 500 ciclos acumulan tensión interna en las partículas activas, lo que provoca grietas transversales que degradan el rendimiento de la batería. En el procesamiento seco, la red de fibrillas recubre los materiales activos, manteniendo su integridad estructural después de 500 ciclos con mínimas grietas superficiales. La estructura de malla también suprime la expansión del material activo, evita que las partículas se desprendan de los colectores de corriente y mejora la estabilidad y el rendimiento eléctrico.

Contáctanos para más información sobre nuestros

soluciones de electrodos secos

.