La estabilidad y dispersabilidad de la batería. La lechada tiene un impacto importante en las propiedades de los electrodos y acabado. productos de batería. Entonces, ¿cómo caracterizar la estabilidad y dispersabilidad de lodo de batería?

Método de caracterización de la batería. estabilidad de la suspensión

1. Método de contenido sólido

El método de prueba de contenido sólido es de bajo costo. y método fácil de probar. Su principio es colocar el purín en un recipiente. y tomar muestras en el mismo lugar a intervalos regulares para probar y analizar el contenido sólido. Al juzgar la diferencia en el contenido sólido, la estabilidad de La suspensión de la batería de litio se puede juzgar para ver si hay sedimentación, estratificación y otros fenómenos.

2. Método de viscosidad

El método de prueba de viscosidad también puede reflejan básicamente la estabilidad de la suspensión. Su principio es colocar el suspensión en un recipiente y probar la viscosidad a intervalos regulares. El La estabilidad de la suspensión se puede juzgar por el cambio de viscosidad.

3. Estabilidad Analizador

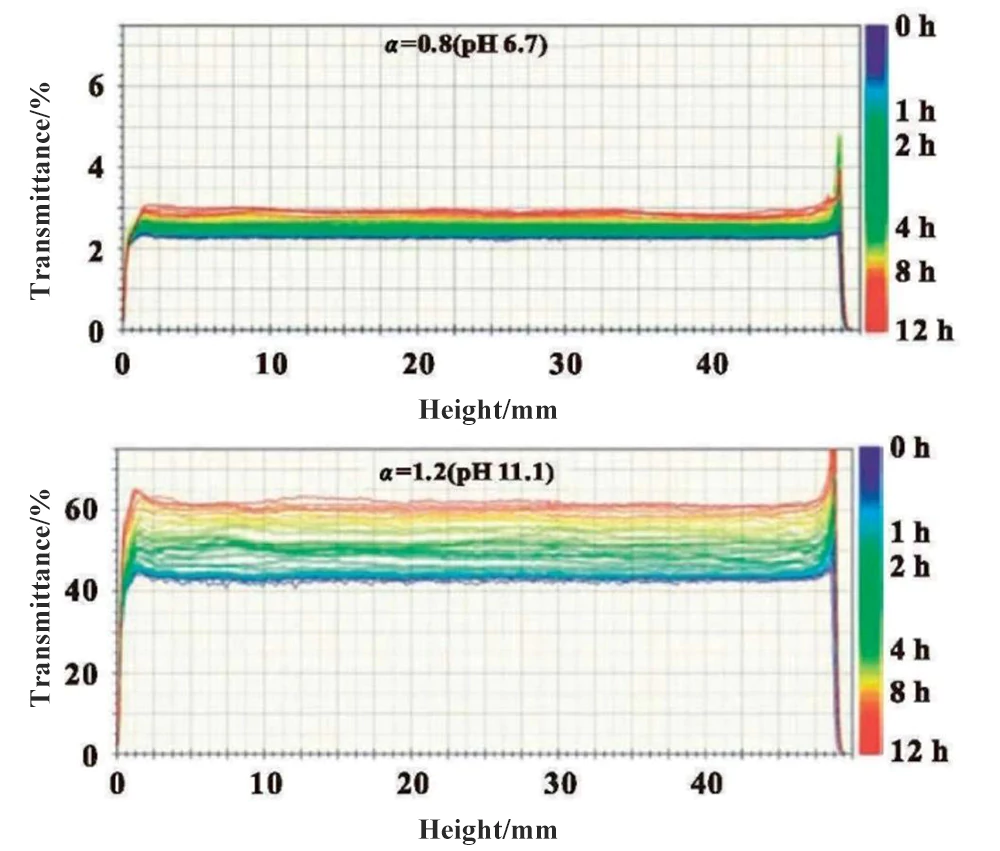

El uso de El analizador de estabilidad puede hablar con datos. Por ejemplo, Sung et al. usó un analizador de estabilidad para monitorear los cambios de transmitancia de luz de diferentes pH lechadas que utilizan PAA como aglutinante en un plazo de 12 horas. La transmitancia de luz inicial. y valores de cambio de 12 horas del neutro los purines eran más pequeños. Debido a que los materiales de negro de humo tienen absorción de luz, Una menor transmitancia de luz indica una mejor dispersión del negro de carbón. Las partículas y los microaglomerados más pequeños tienen áreas de superficie específicas más grandes, mejorando así la eficiencia de absorción de luz. Al mismo tiempo, los pequeños El cambio en la transmitancia de luz de la suspensión dentro de 12 horas indica que la suspensión tiene buena estabilidad de dispersión durante el proceso estático, como se muestra en la figura siguiente.

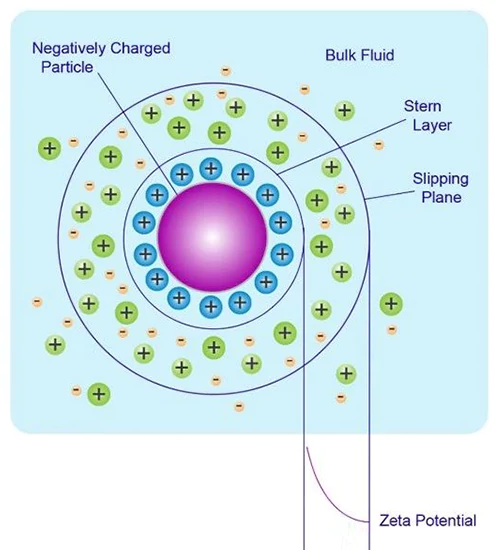

4. Caracterización del potencial Zeta

potencial zeta Se refiere al potencial del plano de corte, también conocido como electrocinético. fuerza potencial o electromotriz, y es un indicador importante para caracterizar la estabilidad de las dispersiones coloidales. Cuanto más pequeñas sean las moléculas o dispersas partículas, mayor será el valor absoluto del potencial Zeta (positivo o negativo), y cuanto más estable sea el sistema, es decir, la disolución o la dispersión puede resistir la agregación. Por el contrario, cuanto menor sea el potencial Zeta (positivo o negativo), más tiende a coagularse o agregarse, es decir, la atracción supera la repulsión, la dispersión se destruye y se produce coagulación o agregación.

Caracterización método de dispersión de lodo de batería

1. finura

La finura es una importante indicador de rendimiento de la lechada de la batería, que puede reflejar información como el tamaño y la dispersión de las partículas de la suspensión. El valor de finura puede utilizarse para comprender si las partículas de la suspensión están dispersas y si los aglomerados están desaglomerados.

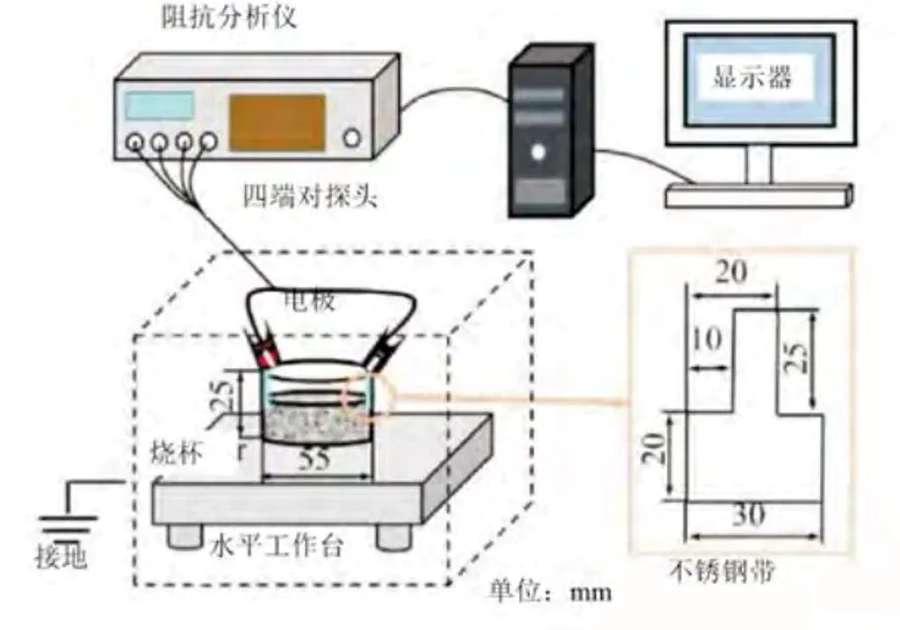

2. Membrana impedancia

batería de litio La suspensión es un sistema mixto sólido-líquido formado por electrodos de dispersión activos. Materiales y agentes conductores en una solución aglutinante. Según el Principio de la prueba de impedancia de membrana de cuatro sondas, la impedancia de membrana de lodo está probado. El estado de distribución del agente conductor en la suspensión puede ser analizado cuantitativamente a través de la resistividad para juzgar el efecto de dispersión de la lechada. El proceso de prueba específico es: use un aplicador de película para cubrir uniformemente la lechada sobre la película aislante, luego calentarla y secarla, medir el espesor del recubrimiento después del secado, corte la muestra y el tamaño cumple con el infinito requisito. Finalmente, use cuatro sondas para medir la membrana del electrodo. impedancia y calcular la resistividad en función del espesor.

3. Exploración microscopía electrónica/análisis del espectro energético/microscopía crioelectrónica

electrón de barrido La microscopía (SEM) se puede utilizar para observar directamente la morfología de la batería. lodo y cooperar con el análisis del espectro de energía (EDS) para analizar la dispersión de cada componente. Sin embargo, al preparar muestras, el secado de la lechada durante este proceso puede causar la redistribución de su propia componentes. La microscopía crioelectrónica (Cryo-SEM) puede mantener el original estado de distribución de los componentes de la pulpa, por lo que recientemente ha comenzado a ser utilizado en el análisis de propiedades de lodos.

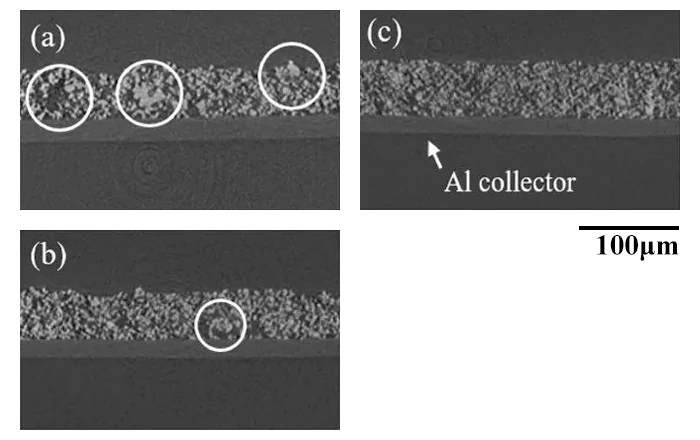

4. Electrodo Imágenes por TC

TC de electrodo Las imágenes pueden observar directamente el estado de dispersión de las partículas en el electrodo. Como se muestra en la siguiente figura, hay más partículas grandes aglomeradas en el electrodo de la Figura a, las partículas aglomeradas en el electrodo en la Figura b se reducen significativamente y casi no hay partículas grandes aglomeradas en el electrodo en la Figura c.

5. Láser tecnología de medición de difracción

difracción láser La tecnología de medición utiliza la teoría de dispersión de Fresnel y la teoría de Fraunhofer para obtener el tamaño y distribución de las partículas. El analizador láser de tamaño de partículas basado En esta tecnología tiene alta precisión de medición, buena repetibilidad y corto tiempo de medición. Ha sido ampliamente utilizado en fábricas de baterías para probar el Tamaño de las partículas de lodo en las baterías.

6. Método de análisis de espectroscopia de impedancia electroquímica

Por ejemplo, Wang et al. utilizó el método de análisis de espectroscopia de impedancia electroquímica (EIS) para directamente un Analizar el espectro de impedancia de la suspensión líquida y obtener el Características electroquímicas de la suspensión a diferentes concentraciones de partículas. Y a través de los resultados del ajuste del espectro de impedancia, se desarrolló un método de evaluación para la estructura de distribución interna de partículas de la suspensión de electrodos basada en Se estableció el modelo de circuito equivalente de parámetros, lo que proporcionó una nueva idea para la medición en línea y la evaluación en línea de la información interna Estructura no uniforme de la suspensión de la batería de iones de litio. El principio de prueba EIS se muestra en la figura.

Métodos para caracterizando tanto la estabilidad como la dispersabilidad de la suspensión

1. Reómetro

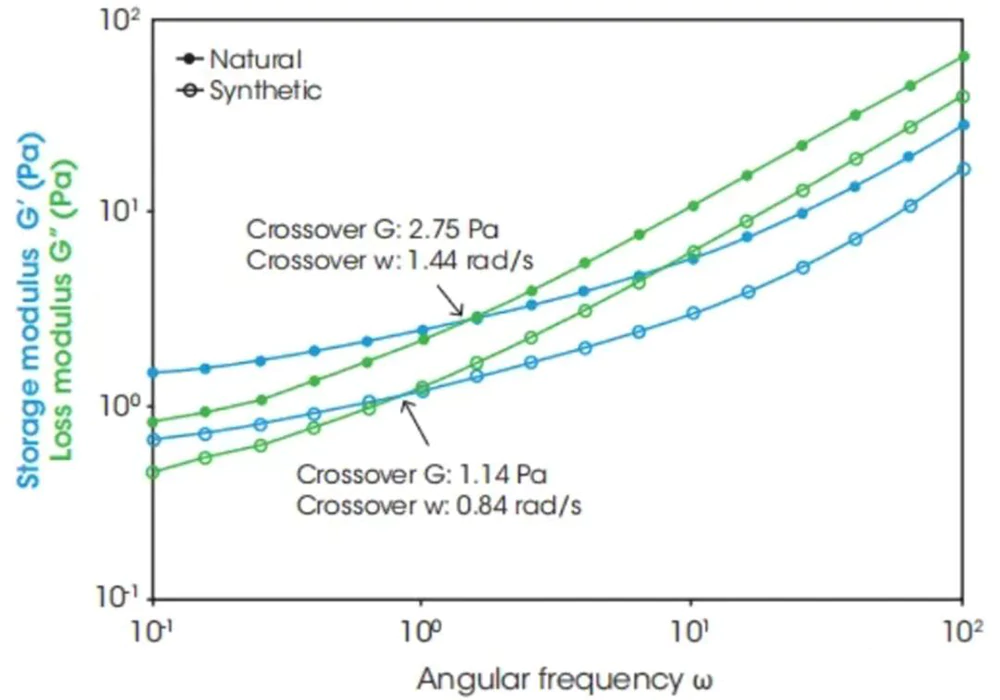

(1) Prueba de viscoelasticidad

Las características viscoelásticas de la pulpa se caracterizan por los valores relativos del módulo de almacenamiento (Gâ²) y el módulo de pérdida (Gâ³). El módulo de almacenamiento Gâ², también conocido como módulo elástico, representa la capacidad almacenada cuando la pulpa sufre deformación elástica reversible y es una medida de la deformación elástica de la lechada. El módulo de pérdida Gâ³, también conocido como módulo viscoso, representa la energía consumida cuando la suspensión se somete deformación irreversible y es una medida de la deformación viscosa del estiércol líquido. En el escaneo de frecuencia, basándose en el tamaño relativo de Gâ² y Gâ³ y evaluando la sensibilidad de Gâ² a la frecuencia angular, es posible reflejar si el la suspensión se encuentra en estado fluido o en estado sólido. En el rango de baja frecuencia, Gâ²Gâ³y cuanto mayor sea la diferencia, mayor Mejor la estabilidad de la pulpa. Como se muestra en la siguiente figura, la estabilidad de la suspensión de grafito natural es mejor que la de la suspensión de grafito sintético.

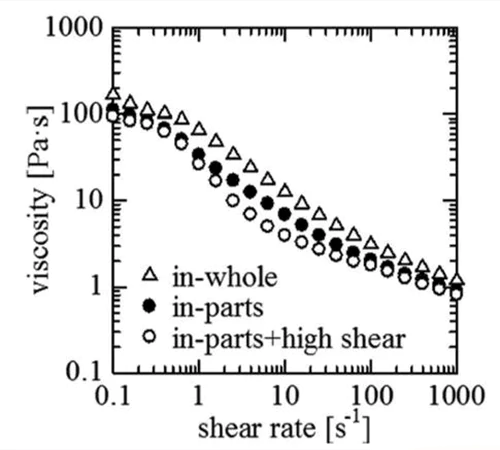

(2) Cambiosen viscosidad con velocidad de corte

La viscosidad de una suspensión generalmente cambia con la velocidad de corte. Cuando existe un comportamiento de adelgazamiento por corte, Hay aglomerados blandos en la pulpa que se destruyen fácilmente con el corte. estrés. Por el contrario, la presencia de engrosamiento por cizallamiento suele indicar que hay partículas agregadas duras en la lechada. En términos generales, las lechadas con velocidades de adelgazamiento por cizallamiento más rápidas tienden a tener una mejor dispersabilidad, ignorando la destrucción del aglutinante por la fuerza de corte. Como se muestra en la figura A continuación, la suspensión representada por el círculo hueco tiene mejor dispersabilidad. que las otras dos lechadas.

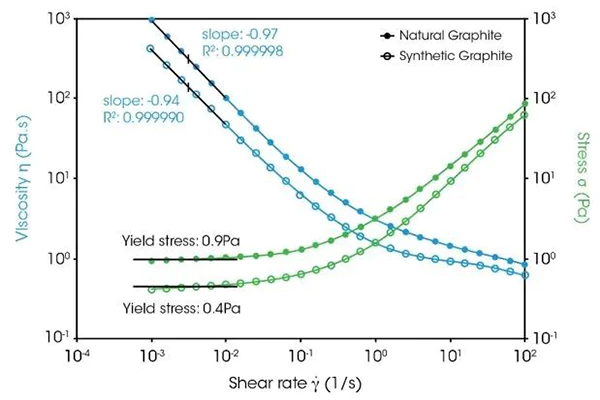

(3) Rendimiento prueba de estrés

El límite elástico En reología se define como la tensión aplicada a la que el plástico irreversible La deformación se observa primero en la muestra. Teóricamente, el límite elástico es la tensión mínima requerida para iniciar el flujo. El análisis de rendimiento es importante para todos los fluidos estructurados complejos. Ayuda a comprender mejor el producto. rendimiento, como la vida útil y la estabilidad contra la sedimentación o la fase separación. Hay una variedad de métodos reológicos que se pueden utilizar para determinar el límite elástico. La siguiente figura muestra el análisis del límite elástico. utilizando el método de reducción del flujo de corte. De los resultados de la prueba, se puede ver. que a velocidades de corte moderadas, el esfuerzo cortante disminuye a medida que la velocidad de corte disminuye. Sin embargo, cuando la velocidad de corte se reduce aún más, la curva de tensión alcanza un nivel estable y es independiente de la tasa. Este valor de tensión estable se llama punto de cedencia. Al mismo tiempo, la medida "aparente La curva de "viscosidad" se vuelve infinita y tiene una relación lineal con la velocidad de corte cuando la pendiente es -1.

Desde sintético El grafito tiene un tamaño de partícula más grande y una forma de partícula más irregular, el la lechada exhibe un límite elástico más bajo y una estructura de red más débil. Por lo tanto, Esta muestra de suspensión de grafito sintético será más susceptible a la sedimentación. y separación de fases. La sedimentación del lodo puede provocar una distribución desigual del materiales activos en el electrodo, lo que reduce el rendimiento de la batería.

(4) Tixotropía

Después del recubrimiento, La lechada de la batería se nivelará bajo la acción de la gravedad y la tensión superficial. en el colector actual. En el rango de velocidad de corte baja, se espera que el La viscosidad volverá gradualmente a la alta viscosidad antes del recubrimiento. antes de eso vuelve a una alta viscosidad, la viscosidad de la suspensión sigue siendo relativamente baja, fácil de nivelar y la superficie del recubrimiento es lisa y de espesor uniforme. El El tiempo de recuperación no debe ser demasiado largo ni demasiado corto. Si el tiempo de recuperación es demasiado de largo, la viscosidad de la lechada será demasiado baja durante el proceso de nivelación, y es fácil tener cola o el espesor del borde inferior es mayor que el espesor del revestimiento superior. Si el tiempo es demasiado corto, la lechada no tendrá tiempo de subir de nivel.

2. Estiércol líquido medidor de resistencia

la lechada El parámetro de resistividad tiene una correlación significativa con la fórmula de la suspensión. el tipo y contenido del agente conductor, el tipo y contenido del aglutinante, etc. Después de agitar la suspensión y dejarla reposar durante un período de tiempo, puede ocurrir sedimentación del gel y el valor de resistividad también se mostrará diferentes grados de cambio. Por lo tanto, la resistividad de la suspensión se puede utilizar como un Método para caracterizar la uniformidad y estabilidad de la electricidad de la pulpa. propiedades.

Método de prueba: poner un cierto volumen de suspensión (aproximadamente 80 ml) en el vaso medidor, inserte un Limpiar la pluma del electrodo, iniciar el software, probar el cambio de resistividad de la lechada. en tres pares de electrodos a lo largo del tiempo y guárdelo en el documento.

Parámetros de prueba: resistividad, temperatura, tiempo

Cálculo fórmula: Resistividad (Ω*cm):Ρe=U/I * S/L

Características:

1. Separe el Líneas de voltaje y corriente, elimina la influencia de la inductancia en el voltaje. medición y mejorar la precisión de la detección de resistividad.

2. los 10 mm El electrodo de disco de diámetro garantiza un área de contacto relativamente grande con la muestra. y reduce el error de prueba.

3. El cambio de resistividad en tres posiciones en la dirección vertical de la suspensión a lo largo del tiempo se puede monitorear en tiempo real.

Resistividad rango de medición: 2.5Ω*cm~50MΩ*cm

Resistividad Precisión de medición:±0,5%